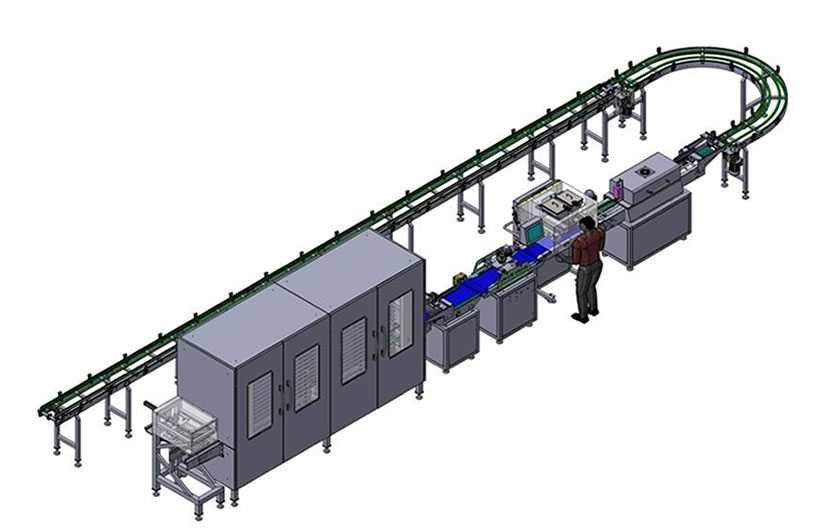

The moulding line is developed with extreme attention to the hygienic design; Its high modularity allows different types of configuration for any type of products: solid, solid with inclusions, one shot (center filled products). The line is suitable for producing high quality products with low capacity or start-ups.

Moulding line is designed to suit low to medium capacity compound/ chocolate slab manufacturers. Its high modularity allows different types of configuration for any type of production: solid, solid with inclusions, one shot (center filled products).